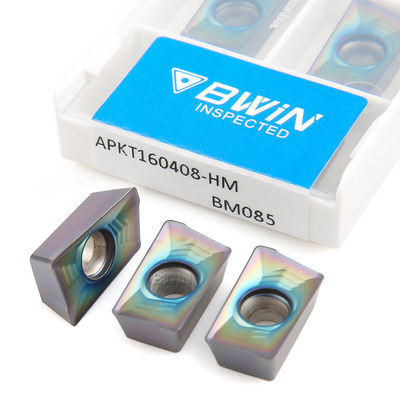

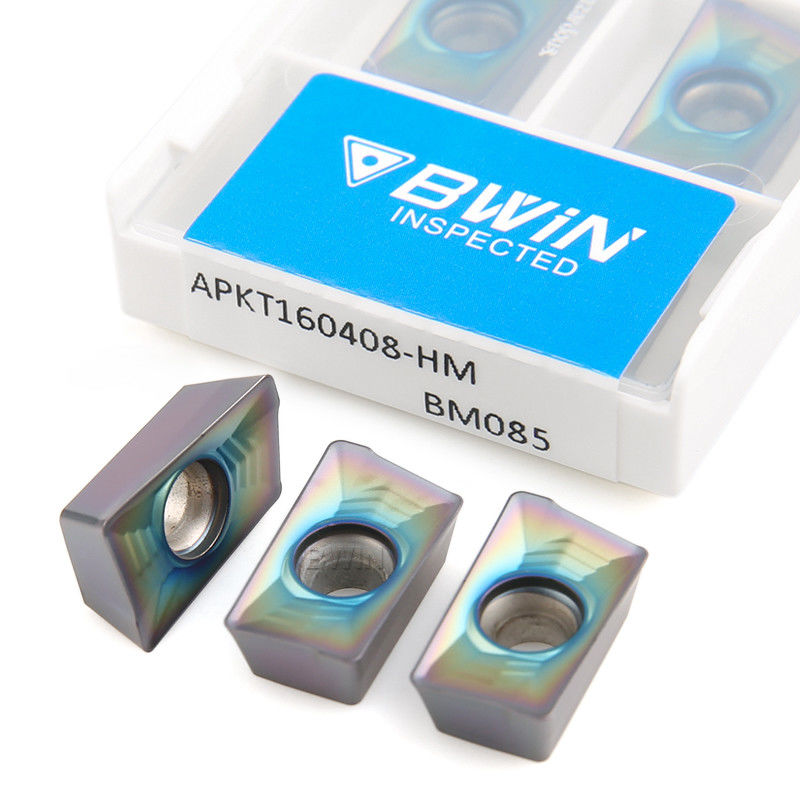

Sharp Edge Apkt 1604 Carbide Inserts

Product Details:

| Place of Origin: | China |

| Brand Name: | BWIN |

| Model Number: | Apkt1604 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10pcs/box |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic box |

| Delivery Time: | 7 work days |

| Payment Terms: | T/T, Western Union, |

| Supply Ability: | 1-10000pcs 7days |

|

Detail Information |

|||

| Product Name: | Apkt 1604 Milling Insert | Model: | Apkt 1604 1003 1135 Apkt160408 |

|---|---|---|---|

| Color: | No-coated/Fuchsia/Black | Workpiece: | Stainless Steel/Cast Iron/Aluminum/Steel |

| Hardness: | HRA92.4 | Feature: | Processing Efficiency |

| Usage: | Milling Machining | Advantage: | Stable Performance |

| Processing Type: | Medium Cutting | Customized Support: | OEM, ODM |

| Highlight: | Lathe Turning Insert Sharp Edge,Lathe Turning Insert Apkt 1604,Sharp Edge Apkt 1604 Carbide Inserts |

||

Product Description

Apkt 1604 Milling Insert Carbide Face Cutter Cutting 1003 1135 Apkt160408

Quick Detail:

- Sharp edge

- Durable

- Processing efficiency

- Stable performance

- High finish

Description:

- The high heat resistance and cobalt rich gradient structure cemented carbide matrix ensures the high stability of the cutting edge. The blade has good resistance to high temperature, thermal shock and oxidation. It can be processed at high speed without cutting fluid and is more convenient to use; The blade is sharp and does not stick to the knife, reducing friction; Low cutting force, reduce wear; The fine density alloy substrate is coated with H01 film, which makes the blade surface smooth, reduces friction, is not easy to stick, has good wear resistance, strong deformation resistance and long service life; Smooth cutting, good chip removal performance, no chip buildup, good surface finish, suitable for finishing and semi finishing

Specifications:

| Brand | BWIN |

| Model | Apkt1003/Apkt1135/Apkt1604/Apkt1605/Apkt160408 |

| Color | Black/Fuchsia/No-coated |

| Workpiece | Steel/Cast iron/Stainless steel/Aluminum |

| Type | Cnc Milling Carbide Insert |

| Material | Tungsten CNC Carbide Milling Insert |

| Processing Type | Medium Cutting |

| Feature | Sharp edge |

| Durable | |

| Processing efficiency | |

| Stable performance | |

|

High finish |

|

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

![]()

|

Modle

|

l(mm)

|

d(mm)

|

t(mm)

|

|

APMT1135

|

11

|

6.35

|

3.5

|

|

APMT1604

|

16.5

|

9.525

|

4.76

|

|

APMT1605

|

16.5

|

9.525

|

5.1

|

|

APKT1003

|

6.67

|

3.55

|

2.8

|

|

APKT160408

|

17.5

|

9.525

|

5.77

|

Notice:

1. Reasonable selection of cutting parameters:

Processing materials, cutting tools and cutting conditions are the three major elements

2. Reasonable tool selection:

(1) During rough turning, tools with high strength and good durability shall be selected to meet the requirements of large back cutting and large feed during rough turning.

(2) During fine turning, tools with high accuracy and good durability shall be selected to ensure the requirements of machining accuracy.

(3) In order to reduce the tool change time and facilitate tool setting, machine clamp knives and machine clamp blades shall be used as far as possible.

The three elements of cutting conditions: cutting speed, feed rate and cutting depth directly cause tool damage.

3. Reasonable selection of fixtures:

(1) The general fixture shall be selected as far as possible to clamp the workpiece, and the special fixture shall be avoided;

(2) The part positioning datum is coincident to reduce the positioning error.

4. Determine the processing route:

The processing route refers to the path and direction of the tool relative to the part during the processing of the NC machine tool.

(1) The requirements for machining accuracy and surface roughness shall be guaranteed;

(2) The machining route shall be shortened as far as possible to reduce the tool idle travel time.

Applications:

Our tungsten milling carbide insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

![]()

A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable.

Q2. What about the lead time?

A: 3-5 days for Sample preparing ,8-10 working days for mass production.

Q3. Do you have any MOQ limit for carbide insert order?

A: Low MOQ, 1pc for sample checking is available.

Q4. How do you ship the goods and how long does it take to arrive?

A: Ship by DHL, UPS, FedEx or TNT. It takes 3-5 days to arrive. Airline and sea shipping also optional.

Q5. How to proceed an order for carbide insert?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q6. Is it OK to print my logo on carbide insert product?

A: Yes. Please inform us formally before our production.