Tungsten Carbide CNC End Mill Cutter HRC45 / HRC55 / HRC60 / HRC65

Product Details:

| Place of Origin: | China |

| Brand Name: | BWIN |

| Model Number: | D4*20*d4*100L-4F |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs/box |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic box |

| Delivery Time: | 7 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1-10000pcs 7days |

|

Detail Information |

|||

| Product Name: | Tungsten Carbide Milling Cutters | Model: | Various CNC Machining Milling Cutters |

|---|---|---|---|

| Material: | 100% New Material | Workpiece: | Cast Iron, Alloy Steel, Carbon Steel, Etc |

| Coating: | AlTiN/AlTiSiN/TiAlN/Blue Nano | HRC: | HRC45/HRC55/HRC60/HRC65 |

| Feature: | Strong Universality | Application: | CNC Milling Tool |

| Package: | 1pcs/Plastic Box | ||

| Highlight: | Tungsten Carbide CNC End Mill Cutter,HRC45 CNC End Mill Cutter,CNC Freze Carbide End Mill |

||

Product Description

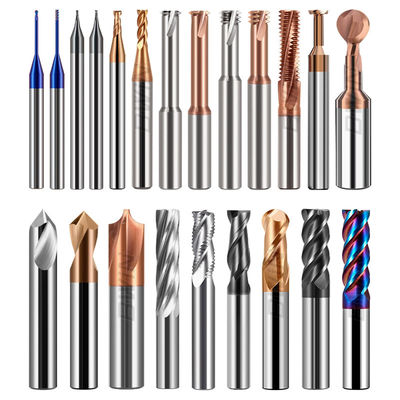

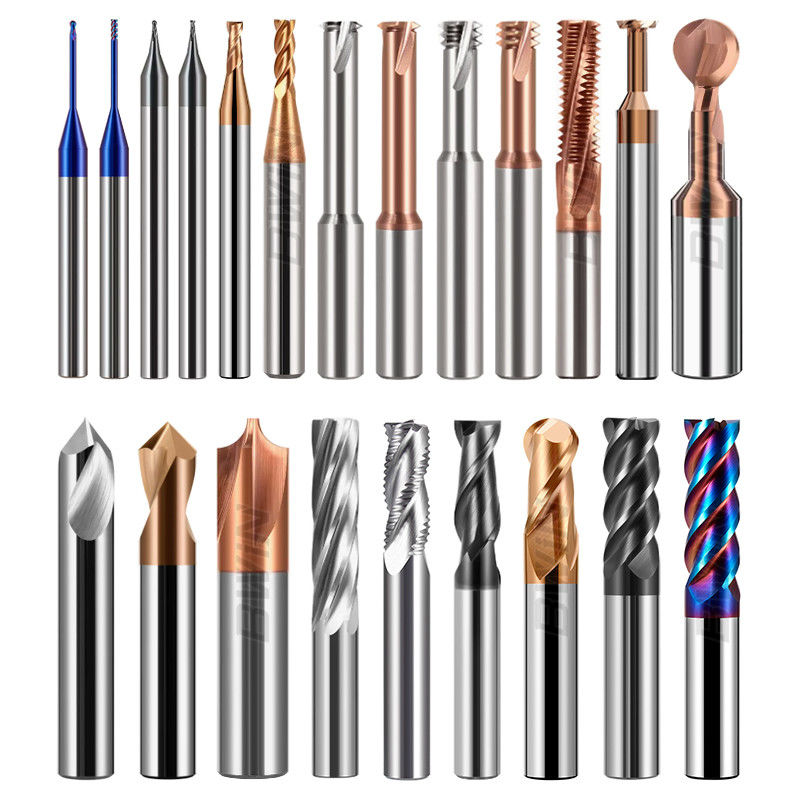

CNC Freze Micro Flat/Ball Nose/Corner Radius/Roughing/Chamfer/Thread Endmill Square End Milling Cutter

We have 10 years of experience in research and development and design of CNC precision tools. Its main products include carbide end mill (including flat end mill, ball nose end mill, corner radius end mill, roughing end mill, dovetail end mill, chamfer end mill, inter-R end mill, T-slot end mill, aluminum end mill, micro diameter end mill, deep groove end mill, arch end mill, etc.), carbide inesrts, drill bits, taps, wrenches, screws, and other CNC precision tools; Support non-standard customization, please contact us for more cooperation details.

Carbide material introdution

| Item Grade |

HRC45

(YG10X )

|

HRC55

(YL10.2 & WF25)

|

HRC60

(Germany K44 &K40)

|

HRC65

(Sandvik H10F)

|

Details |

Grain size 0.7um Co10% Flexural strength 3320N/mm2 |

Grain size 0.6um Co10% Flexural strength 4000N/mm2 |

Grain size 0.5um Co12% Flexural strength 4300N/mm2 |

Grain size 0.5um Co10% Flexural strength 4300N/mm2 |

| Application | Suitable for general steel | General steel, stainless steel, cast iron | High hard material, steel, cast iron, etc | Titanium alloy, high-temperature alloy, harden material, etc |

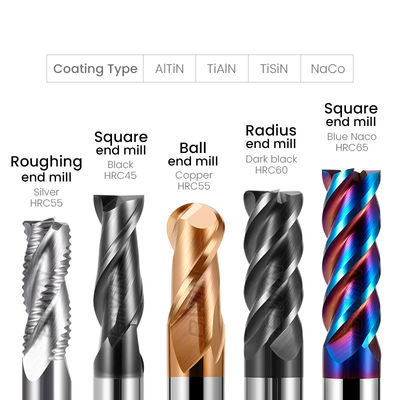

| Coating Classifying and Advantage | |||||

| Item | Coating Type | AlTiN | TiAlN | TiSiN | NaCo |

|

Characteristic

|

Hardness(HV) | 3300 | 2800 | 4300 | 42(GPA) |

| Thickness(UM) | 2.5-3 | 2.5-3 | 3 | 3 | |

| Oxidation Temp.(°C) | 900 | 800 | 1000 | 1200 | |

| Friction Coefficient | 0.35 | 0.3 | 0.25 | 0.4 | |

| Color | Black | Bronze | Bronze and gold | Blue | |

|

Advantages

|

High heat stability |

Normally cutting

|

Suitable for heavy cutting, and high hardness cutting | For high precision cutting | |

| Suitable for high speed, dry cutting | Suitable for cutting mould steel,

stainless steel

|

Suitable for high hardness cutting, mould steel processing | |||

| Most suitable for carbide cutting tools, turning insert | |||||

Applications of carbide end mill

Machinable workpieces include cast iron, alloy steel, carbon steel, tool steel, quenched and tempered steel, stainless steel, copper, aluminum alloy, copper alloy, plastic, wood, magnesium alloy, zinc alloy, aluminum parts, etc

![]()

Product Details of carbide end mill

- Large core diameterStable and earthquake resistant

- Large cutting groove no chips

- Accurate chamfering Easy to use

![]()

Square end mill chart

![]()

| Specification | Flute Dia(D) | Flute length(C) | Shank dia(D) | Overall length(L) |

| Φ1x3Cx4x50L |

1.0 |

3 | 4 | 50 |

| Φ2x6Cx4x50L | 2.0 | 6 | 4 | 50 |

| Φ3x8Cx4x50L | 3.0 | 8 | 4 | 50 |

| Φ4x10Cx4x50L | 4.0 | 10 | 4 | 50 |

| Φ5x13Cx6x50L | 5.0 | 13 | 6 | 50 |

| Φ6x15Cx6x50L | 6.0 | 15 | 6 | 50 |

| Φ8x20Cx8x60L | 8.0 | 20 | 8 | 60 |

| Φ6x20Cx6x75L | 6.0 | 20 | 6 | 75 |

| Φ8x25Cx8x75L | 8.0 | 25 | 8 | 75 |

| Φ10x25Cx10x75L | 10.0 | 25 | 10 | 75 |

| Φ12x30Cx12x75L | 12.0 | 30 | 12 | 75 |

| Φ10x40Cx10x100L | 10.0 | 40 | 10 | 100 |

| Φ12x45Cx12x100L | 12.0 | 45 | 12 | 100 |

| Φ14x40Cx14x100L | 14.0 | 40 | 14 | 100 |

| Φ16x40Cx16x100L | 16.0 | 40 | 16 | 100 |

| Φ18x40Cx18x100L | 18.0 | 40 | 18 | 100 |

| Φ20x45x20x100L | 20.0 | 45 | 20 | 100 |

Tips: The above specifications are standard Size, with a large amount of stock. At the same time, we support OEM customized production, the diameter is 0.2mm to 25mm, the Total length is 50mm to 200mm, include inch size end mill , the number of Flute is 4F, 5F, 6F, 8F and the logo could becustomized.

Instructions of carbide end mill

1. Before using the carbide end mill, please measure the tool deflection. If the tool deflection accuracy exceeds 0.01mm, please correct it before cutting.

2. The shorter the carbide extends out of the collet, the better. If the tool extends out longer, reduce the speed, feed speed or cutting amount.

3. In case of abnormal vibration or sound during cutting, please reduce the speed and cutting amount until the situation is improved.

4. Spray type and air jet type are preferred for steel cooling, which can improve the use effect of carbide end mill.

5. Note: Not suitable for low speed machines such as rotary table and electric hand drill.

Advantage

- Factory---We have our own factory with modern standard indexable blade production lines, CNC turning tool bar production lines, overall carbide end mill production lines, and PVD coating production lines; The product specifications and models are complete, and can be designed and produced according to customers' non-standard customization needs;

- Sample---Support free samples, sample preparation for 3-5 days, mass production for 8-10 working days;

- Logistics---Our shipping channels include sea, land, and air transportation;

- After sales---We have a complete after-sales system, and cooperation is not the end, it is the beginning. If you have any after-sales problems, please feel free to contact us, and we will solve them for you as soon as possible.

FAQ