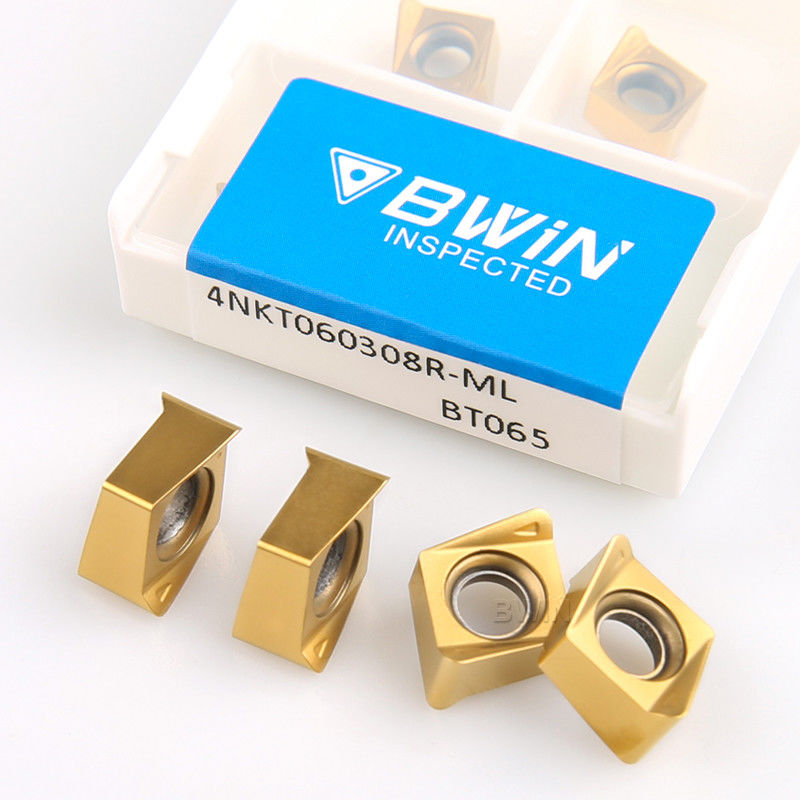

Custom Milling Cnc Carbide Inserts 4nkt060308 4nkt 060308r 06 Fast Feeding Cutter

Product Details:

| Place of Origin: | China |

| Brand Name: | BWIN |

| Model Number: | 4nkt060308 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10pcs/box |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic box |

| Delivery Time: | 7 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1-10000pcs 7days |

|

Detail Information |

|||

| Product Name: | Custom Milling Carbide Insert 4nkt060308 | Material: | Tungsten Carbide Milling Insert |

|---|---|---|---|

| Workpiece: | Steel | Usage: | Milling |

| Color: | Yellow | Coating: | PVD CVD |

| Hardness: | HRC40-60 | Feature: | Fast Feed Cnc Carbide Milling Insert |

| Application: | CNC Lathe Machine Fast Feeding Cutting Tool | Package: | 10pcs/Box |

| Highlight: | Custom Milling Cnc Carbide Inserts,Cnc Carbide Inserts 4nkt060308,Milling Carbide Insert Fast Feeding Cutter |

||

Product Description

Custom Milling Cnc Carbide Insert 4nkt060308 4nkt 060308r 06 Fast Feeding Cutter

Quick Detail:

- Alloy material

- High stability

- High efficiency

- Smooth cutting

- Good heat dissipation condition

- Wide application

Description:

- The cnc carbide inserts made of high-quality tungsten steel alloy, which is wear-resistant and durable overall, with smooth and polished surface and effective corrosion resistance; Innovative high-energy coating process, high nano hardness, reduced surface friction, reduced cutting resistance, low friction coefficient, high oxidation resistance temperature; Complete models, corresponding to various angles

Specifications:

| Brand | BWIN |

| Model | 4nkt060308 |

| Color | Yellow |

| Workpiece | Steel |

| Type | Milling cnc carbide inserts |

| Material | Tungsten Carbide Milling Insert |

| Processing | Medium Cutting |

| Feature | High Hardness |

| High Stability | |

| Smooth Cutting | |

| High Finish Polished | |

| Shock and vibration resistance | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice:

- The cnc carbide inserts shall not be collided or dropped on the ground and must be handled with care.

- Before installing the cnc carbide inserts, the performance and purpose of the saw table must be confirmed to ensure that the cutting direction indicated by the blade arrow is consistent with the rotation direction of the saw table. It is strictly prohibited to install in the opposite direction. Wrong installation direction may cause the blade sawtooth to fall off, so as to prevent accidents.

- After installation, it is necessary to confirm whether the central hole of the cnc carbide inserts are firmly fixed on the flange plate of the saw table. If there is a gasket, the gasket must be sleeved; Then, gently push with your hand to confirm whether the blade rotates eccentrically.

- When using, do not exceed the specified high speed

- When the cnc carbide inserts are not used, hang the blade vertically on the dry shelf.

Applications:

Our cnc carbide inserts could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

![]()

FAQ

1. Flank Wear? Higher cutting resistance,Notch wear on flank,Poor roughness of surface, or deterioration of accuracy.

Soft grades,Excessive cutting speed,Small flank angle,Low feed.

Select a higher,wear-resistant grade,Reduce cutting speed,Increase flank angle,Increase feed.

2. Crater Wear? Uncontrolled chip,Poor surface quality,when finishing High speed processing carbon steel

Soft grades,Excessive cutting speed,Excessive feed,The strength of chip breaker Insufficiet.

Change to a higher wear-resistant grade,Reduce cutting speed,Reduce feed,Select a higher strength chip breaker.

3. Chipping? Sudden fracture of cutting edge(rake face and flank),Instability insert life

Toughness insufficient,Excessive feed rate,Strength of cutting edge insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of cutting edge(chamfering to rounding),Increase the stability and setting angle

4. Insert Fracture? Cutting resistance increased Poor surface roughness.

Toughness insufficient,Excessive feed rate,Strength of cutting edge insufficient,Instability of the tool.

Select a tougher grade,Decrease feed rate,Increase honing of cutting edge(chamfering to rounding),Increase the stability and setting angle.

5. Plastic Deformation? Variation of dimension Nose wear,cutting edge drape or passivating.when processing alloy steel Poor surface roughness

Soft grade,Excessive cutting speed,Excessive cutting depth and feed rate,Overheat on cutting edge.

Select a higher red hardness cutting material,Decrease cutting speed,Decrease cutting depth and feed rate,Select a higher thermal conductivity cutting material(CVD+sufficient coolant).

6. Build-Up-Edge? Workpiece dissove with Cutting edge Poor surface roughness when finishing,Cutting resistance increased,Cutting soft materials.

Cutting speed too low,Cutting edge obtuse,Unsuitable tool material. Increase cutting speed,Increase rake angle,Select small sticking force.

Want to Know more details about this product