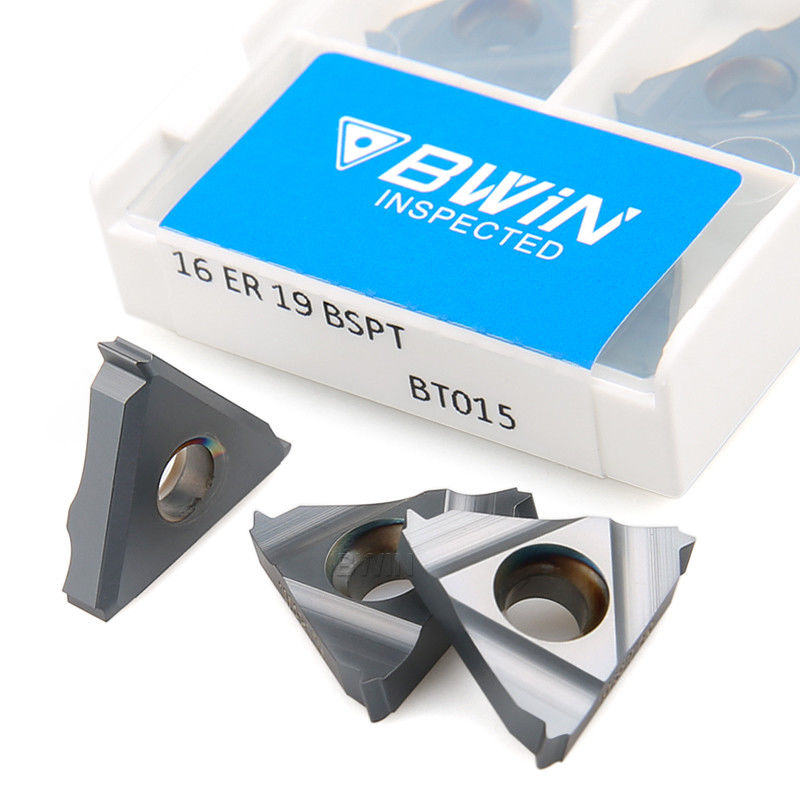

BSPT 11 19 Carbide Lathe Insert Wear Resistance Thread Turning Inserts

Product Details:

| Place of Origin: | China |

| Brand Name: | BWIN |

| Model Number: | 16IR 14BSPT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 10pcs/box |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plastic box |

| Delivery Time: | 7 work days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1-10000pcs 7days |

|

Detail Information |

|||

| Product Name: | BSPT Threading Carbide Lathe Insert | Material: | Externa Cemented Carbide Threading Insert |

|---|---|---|---|

| Workpiece: | Stainless Steel/Steel/Cast Iron | Usage: | CNC Tool |

| Color: | Yellow/Black | Coating: | PVD/CVD |

| Hardness: | HRC40-HRC60 | Feature: | High Strength Cutting Edge |

| Application: | CNC Machine Tool | Package: | 10pcs/Box |

| Highlight: | BSPT 11 19 Carbide Lathe Insert,Wear Resistance Thread Turning Inserts,Carbide Lathe Insert Wear Resistance |

||

Product Description

16er 16ir 14 BSPT 11 19 Carbide Lathe Insert External Cemented Tungsten Tool Machining

Quick Detail:

- Excellent material

- Durable

- Wear resistance

- Sharp blade

- Not easy to break the knife

- High cutting efficiency

Description:

-

This cnc carbide lathe insert is made of 100% pure carbide powder, with excellent wear resistance and toughness; Refine nano matrix, and improve the overall stability with constancy; Innovative high-energy coating process, high nano hardness, low friction coefficient and high oxidation resistance temperature; The blade has strong versatility, can process a variety of workpieces, and has high cost performance; The blade is more sharp and shock resistant, and the chip breaking is smooth without sticking to the blade, which is not easy to collapse; Customizable plug-in design, coating, marking and packaging.

Specifications:

| Brand | BWIN |

| Model | 16ER/16IR 14BSPT |

| Color | Black/Yellow |

| Workpiece | Cast iron/Stainless steel/Steel |

| Type | Cnc Metal Carbide Lathe Insert |

| Material | Tungsten Carbide Threading Inserts |

| Processing Type | Medium Cutting |

| Feature | Excellent material |

| Durable | |

| Wear resistance | |

| Sharp blade | |

| High cutting efficiency | |

| Standard | ISO |

| Quantity | 10pcs/box |

| Weight | 0.015kg |

| Package | Plastic Box |

| Customized Support | OEM, ODM |

Lead Time:

| antity(pieces) | 1 - 3000 | >3000 |

| Lead time (days) | 7 | To be negotiated |

Notice:

- The carbide lathe insert shall not be collided or dropped on the ground and must be handled with care.

- Before installing the carbide lathe insert , the performance and purpose of the saw table must be confirmed to ensure that the cutting direction indicated by the blade arrow is consistent with the rotation direction of the saw table. It is strictly prohibited to install in the opposite direction. Wrong installation direction may cause the blade sawtooth to fall off, so as to prevent accidents.

- After installation, it is necessary to confirm whether the central hole of the carbide lathe insert is firmly fixed on the flange plate of the saw table. If there is a gasket, the gasket must be sleeved; Then, gently push with your hand to confirm whether the blade rotates eccentrically.

- When using, do not exceed the specified high speed

- When the carbide lathe insert is not used, hang the blade vertically on the dry shelf.

Applications:

Our carbide lathe insert could to be processed Alloy steel, Tool steel, carbon steel, stainless steel, Cast iron and Titanium alloy. Working material as following:

![]()

Advantages:

1. Honest merchants, reasonable price and quality assurance

2. Large inventory, sufficient supply and high cost performance

3. Customer service responds in time and delivers goods quickly

4. Provide after-sale guarantee to make your after-sale service free

1. Rear cutter face wear: (This is a common practical form)

Influence: the workpiece size gradually changes or the surface light intensity decreases

Cause: The linear speed is too high, reaching the service life of the tool

Measures: Adjust the processing parameters, such as reducing the linear speed and using a blade with higher wear resistance

2. Blade breakage: (bad actual effect form)

Effect: sudden change of workpiece size or surface smoothness, resulting in burrs on the spark surface

Cause: Improper parameter setting, improper tool face material selection, poor workpiece rigidity, unstable blade clamping Measures: check whether the parameter setting is reasonable, and select the corresponding tool according to the workpiece material

3. Serious fracture: (very bad actual effect form)

Effect: sudden and unexpected occurrence, resulting in scrapping of tool handle materials or defective and scrapped workpieces

Cause: The processing parameters are set incorrectly, and the vibrating tool workpiece or blade is not installed in place

Measures: set reasonable parameters, reduce the feed rate and chip, select the corresponding processing blade, and strengthen the rigidity of the workpiece and blade

4. Chips:

Effect: the size of the workpiece is inconsistent, the surface finish is poor, and the workpiece surface is attached with fluff or burrs. Cause: the cutting speed is too low, the feed is too low, and the blade is not sharp enough

Measures: improve the cutting speed, and use blades with higher sharpness for feed rate